Warning: Make sure the router bit is properly fastened and tightened in the router’s collet and the bit can rotate freely without any obstructions.

Instructions: Slowly dial up the RPMs on your router to the recommended maximum. Then, dial back if needed to find the “sweet spot”. The sweet spot is the speed at which the least resonant vibration is present. If the sweet spot cannot be achieved within 5,000 RPMs of the max, check the collet for residue or other debris and start over.

Download Router Bit RPM Chart

|

Bit Diameter (Inches)

|

Max RPM

|

Min RPM

|

|---|---|---|

|

1

|

24,000

|

19,000

|

|

1.1

|

24,000

|

19,000

|

|

1.2

|

24,000

|

19,000

|

|

1.3

|

24,000

|

19,000

|

|

1.4

|

24,000

|

19,000

|

|

1.5

|

24,000

|

19,000

|

|

1.6

|

22,500

|

17,500

|

|

1.7

|

21,100

|

16,100

|

|

1.8

|

20,000

|

15,000

|

|

1.9

|

18,900

|

13,900

|

|

2

|

18,000

|

13,000

|

|

2.1

|

17,100

|

12,100

|

|

2.2

|

16,300

|

11,300

|

|

2.3

|

15,600

|

10,600

|

|

2.4

|

15,000

|

10,000

|

|

2.5

|

14,400

|

9,400

|

|

2.6

|

13,800

|

8,800

|

|

2.7

|

13,300

|

8,300

|

|

2.8

|

12,800

|

7,800

|

|

2.9

|

12,400

|

7,400

|

|

3

|

12,000

|

7,000

|

|

3.1

|

11,600

|

6,600

|

|

3.2

|

11,200

|

6,200

|

|

3.3

|

10,900

|

5,900

|

|

3.4

|

10,500

|

5,500

|

|

3.5

|

10,200

|

5,200

|

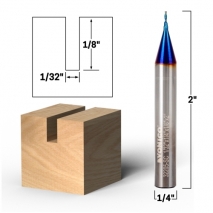

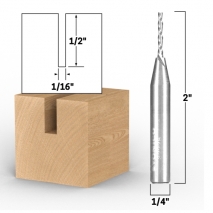

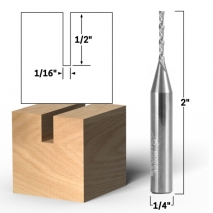

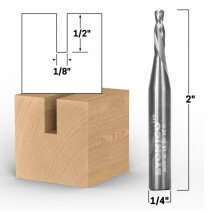

Down cut CNC end mills are great for dado, pocket and inlay work as well as the final pass on most projects. These bits are especially useful when routing material such as melamine and plywood. Down cut spiral bits are designed to produce perfectly clean edges on the top face of the work piece but since the bit’s geometry causes the wood chips to travel in a downward direction, which will cause the tool path to be obstructed, it should only be used in applications where the desired finish is required.