Warning: Make sure the router bit is properly fastened and tightened in the router’s collet and the bit can rotate freely without any obstructions.

Instructions: Slowly dial up the RPMs on your router to the recommended maximum. Then, dial back if needed to find the “sweet spot”. The sweet spot is the speed at which the least resonant vibration is present. If the sweet spot cannot be achieved within 5,000 RPMs of the max, check the collet for residue or other debris and start over.

Download Router Bit RPM Chart

|

Bit Diameter (Inches)

|

Max RPM

|

Min RPM

|

|---|---|---|

|

1

|

24,000

|

19,000

|

|

1.1

|

24,000

|

19,000

|

|

1.2

|

24,000

|

19,000

|

|

1.3

|

24,000

|

19,000

|

|

1.4

|

24,000

|

19,000

|

|

1.5

|

24,000

|

19,000

|

|

1.6

|

22,500

|

17,500

|

|

1.7

|

21,100

|

16,100

|

|

1.8

|

20,000

|

15,000

|

|

1.9

|

18,900

|

13,900

|

|

2

|

18,000

|

13,000

|

|

2.1

|

17,100

|

12,100

|

|

2.2

|

16,300

|

11,300

|

|

2.3

|

15,600

|

10,600

|

|

2.4

|

15,000

|

10,000

|

|

2.5

|

14,400

|

9,400

|

|

2.6

|

13,800

|

8,800

|

|

2.7

|

13,300

|

8,300

|

|

2.8

|

12,800

|

7,800

|

|

2.9

|

12,400

|

7,400

|

|

3

|

12,000

|

7,000

|

|

3.1

|

11,600

|

6,600

|

|

3.2

|

11,200

|

6,200

|

|

3.3

|

10,900

|

5,900

|

|

3.4

|

10,500

|

5,500

|

|

3.5

|

10,200

|

5,200

|

Best for achieving a smooth finish on laminate or veneer finish applications.

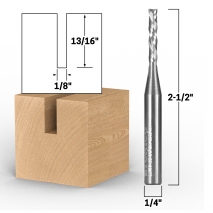

- Cutting Diameter: 1/4"

- Cutting Height: 1"

- Shank Diameter: 1/4"

- Overall Length: 2-1/2"

- Flutes: 3

Compression bits cut down from the top of the stock and up from the bottom of the stock simultaneously. The bit's unique and complex geometry forces the trimmed material to be compressed toward the center of the stock leaving behind a smooth & sharp finish free of chips on both the top and bottom edges. This bit can also be used for mortising projects that require a smooth bottom surface without sacrificing the mortised edge finish.

Pros: Produces smooth edges and mortises on veneer and laminate materials.

Cons: Less than optimal chip removal when dadoing or plunging.

(Choose an up cut spiral bit for standard more efficient milling.)

For use in CNC milling and carving machines.