Warning: Make sure the router bit is properly fastened and tightened in the router’s collet and the bit can rotate freely without any obstructions.

Instructions: Slowly dial up the RPMs on your router to the recommended maximum. Then, dial back if needed to find the “sweet spot”. The sweet spot is the speed at which the least resonant vibration is present. If the sweet spot cannot be achieved within 5,000 RPMs of the max, check the collet for residue or other debris and start over.

Download Router Bit RPM Chart

|

Bit Diameter (Inches)

|

Max RPM

|

Min RPM

|

|---|---|---|

|

1

|

24,000

|

19,000

|

|

1.1

|

24,000

|

19,000

|

|

1.2

|

24,000

|

19,000

|

|

1.3

|

24,000

|

19,000

|

|

1.4

|

24,000

|

19,000

|

|

1.5

|

24,000

|

19,000

|

|

1.6

|

22,500

|

17,500

|

|

1.7

|

21,100

|

16,100

|

|

1.8

|

20,000

|

15,000

|

|

1.9

|

18,900

|

13,900

|

|

2

|

18,000

|

13,000

|

|

2.1

|

17,100

|

12,100

|

|

2.2

|

16,300

|

11,300

|

|

2.3

|

15,600

|

10,600

|

|

2.4

|

15,000

|

10,000

|

|

2.5

|

14,400

|

9,400

|

|

2.6

|

13,800

|

8,800

|

|

2.7

|

13,300

|

8,300

|

|

2.8

|

12,800

|

7,800

|

|

2.9

|

12,400

|

7,400

|

|

3

|

12,000

|

7,000

|

|

3.1

|

11,600

|

6,600

|

|

3.2

|

11,200

|

6,200

|

|

3.3

|

10,900

|

5,900

|

|

3.4

|

10,500

|

5,500

|

|

3.5

|

10,200

|

5,200

|

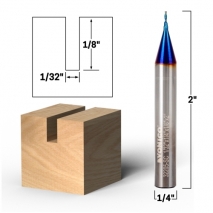

Best for achieving smooth finish on hard plastics.

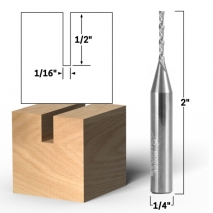

- Cutting Diameter: 1/8"

- Cutting Height: 1/2"

- Shank Diameter: 1/4"

- Overall Length: 2"

- Flutes: 3

Low Helix bits perform a more lateral movement with less lift resulting in a smoother finish. These bits are a better choice for hard plastics such as acrylic and phenolic.

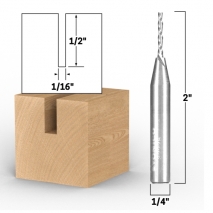

Down cut endmills shear in a downward direction causing the uppermost layer of the material to be pressed down against the material just below it. This motion leaves a perfectly clean top surface edge. A concentration of wood chips in the work path will occur. Hose away excess wood chips to prevent bit breakage.

Pros: Produces smooth finishes on hard plastics,

Cons: Low helix bits require a slower feed rate than "high helix" router bits.

For use in CNC milling and carving machines.