Got a question? Call us at: 732-276-9850 | M-Th 10:00-5:30, Fr 10:00-1:30 Eastern

| Ships From New Jersey.

Best for achieving smooth finish on hard plastics.

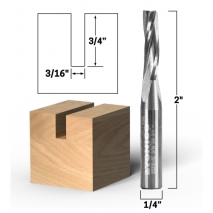

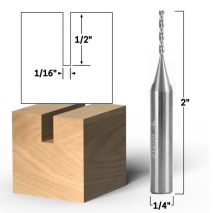

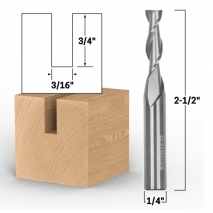

- Cutting Diameter: 1/4"

- Cutting Height: 1"

- Shank Diameter: 1/4"

- Overall Length: 2-1/2"

- Flutes: 3

Low Helix bits perform a more lateral movement with less lift resulting in a smoother finish. These bits are a better choice for hard plastics such as acrylic and phenolic.

Up-cut endmills direct chips up and away from the milling area leaving an unobstructed path for the endmill. Bit breakage is less likely.

Pros: Produces smooth finishes on hard plastics,

Cons: Low helix bits require a slower feed rate than "high helix" router bits.

For use in CNC milling and carving machines.

Bit Specs

Material:

Solid Carbide

Number of Bits:

1

End Mill Type:

Low Helix Upcut

Cut Direction:

Upcut Low Helix

Cutting Diameter:

1/4"

Cutting Length:

1"

Overall Length:

2-1/2"

Number of Flutes:

3

Flute Angle:

7°

General Info

Release Date:

03/17/2015

Condition:

New

Item #:

35314-SC

UPC:

765573829686

Brand:

Yonico

Product Type:

3 Flute Low Helix Upcut Spiral End Mill CNC Router Bit

Manufacturer:

Yonico

MPN:

35314-SC

Weight:

0.08 lbs.