Got a question? Call us at: 732-276-9850 | M-Th 10:00-5:30, Fr 10:00-1:30 Eastern

| Ships From New Jersey.

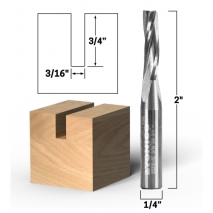

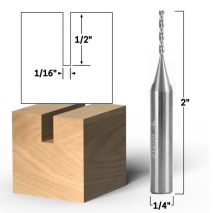

Best used for: Standard milling, dadoing, and boring.

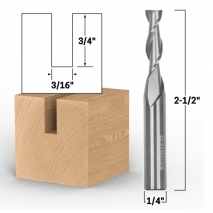

- Cutting Diameter: 1/4"

- Cutting Height: 1"

- Shank Diameter: 1/4"

- Overall Length: 2-1/2"

- Flutes: 2

Up-cut endmills direct woodchips up and away from the milling area leaving an unobstructed path for the endmill. Bit breakage is less likely. Up cut end mills are the best choice for most standard millling applications. The up cut direction can leave behind a minimally rough top surface edge.

Pros: Quick and efficient milling, chip removal.

Cons: Can cause minimal top surface edge roughness or tear-away.

(Choose a down cut spiral bit for projects that require smooth top surface edges.)

For use in CNC milling and carving machines.

Bit Specs

Material:

Solid Carbide

Number of Bits:

1

End Mill Type:

Upcut

Cut Direction:

Upcut

Cutting Diameter:

1/4"

Cutting Length:

1"

Overall Length:

2-1/2"

Number of Flutes:

2

Flute Angle:

28°

General Info

Release Date:

10/28/2014

Condition:

New

Item #:

31215-SC

UPC:

765573828290

Brand:

Yonico

Product Type:

2 Flute Upcut Spiral End Mill CNC Router Bit

Manufacturer:

Yonico

MPN:

31215-SC

Weight:

0.15 lbs.